Understanding BSPT Connection: A Guide to Fittings in Industrial Applications

In today's industrial landscape, the efficiency and reliability of fluid management systems are paramount. Understanding the nuances of different fittings, particularly the BSPT connection, is crucial for maintaining robust and effective systems. This article will delve deeply into BSPT connections, exploring their characteristics, applications, and the various types of fittings that utilize this thread standard.

What is BSPT?

BSPT stands for British Standard Pipe Tapered, a thread standard used for piping systems, predominantly in the UK and other countries that follow imperial measurements. Understanding the significance of BSPT connections is essential for those involved in plumbing, gas applications, and industrial fluid transfer.

The Characteristics of BSPT Connections

- Tapered Threads: BSPT threads are designed to create a seal by tightening and tapering the joint, which aids in preventing leaks.

- Pressure Rating: Depending on the materials and seals used, BSPT connections can handle significant pressures, making them suitable for various applications.

- Compatibility: BSPT threads are compatible with several fittings, ensuring versatility across many types of systems.

Types of Fittings That Utilize BSPT Connections

BSPT connections can be found in different types of fittings, each serving specific purposes in plumbing and industrial applications. Here are some common fittings that utilize BSPT connections:

1. Tube Fittings

Tube fittings play a critical role in connecting pipes and tubing in various systems. BSPT connections in tube fittings ensure a reliable seal, which is vital in preventing leakage in high-pressure systems.

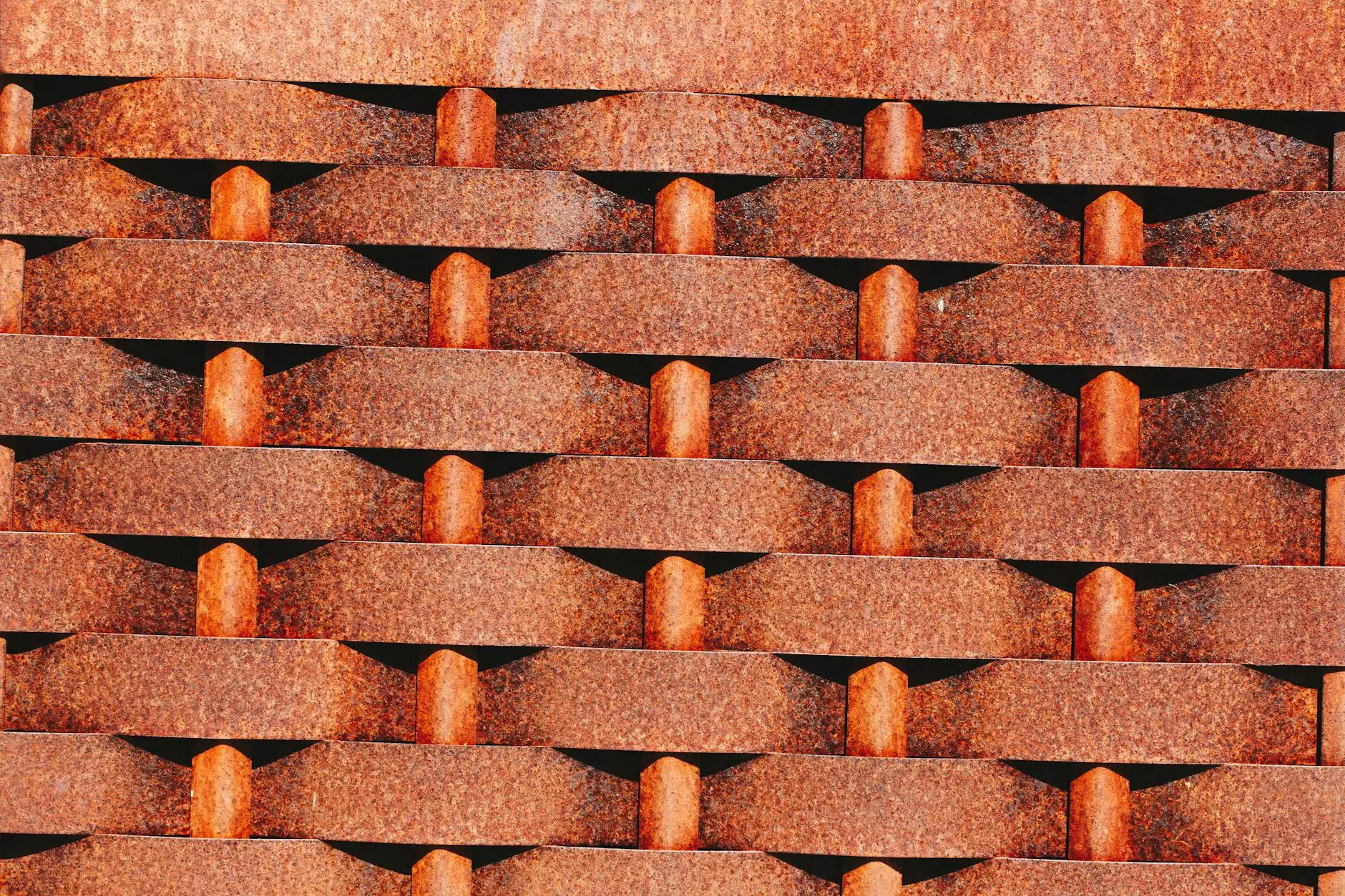

2. Ferrule Fittings

Like tube fittings, ferrule fittings utilize BSPT connections to create leak-proof seals. These fittings are essential in applications requiring seamless connections without compromising flow rates.

3. Forged Pipe Fittings

Forged pipe fittings equipped with BSPT connections are designed to withstand higher pressures and provide durable solutions across various industries, including oil and gas.

4. Threaded Pipe Fittings

Threaded pipe fittings offer easy assembly and disassembly, which is particularly advantageous in maintenance and repair tasks. BSPT-threaded fittings assure that connections maintain integrity under pressure.

5. Flanges

Flanges are critical in creating connections between pipes, valves, and other equipment. The BSPT connection is often utilized in flanges to ensure a secure and tight fit, preventing leaks in critical junctions.

Applications of BSPT Connections

BSPT connections find application across numerous industries due to their versatility and reliability. Here are some notable applications:

- Water Supply Systems: Used in municipal and industrial water supply lines to ensure safe and reliable delivery.

- Oil and Gas: Essential in transporting hydrocarbons where pressure and leak prevention are paramount.

- Manufacturing: Used in various machine interfaces, ensuring fluid systems operate efficiently without leaks.

- HVAC Systems: Utilized in piping for heating, ventilation, and air conditioning systems, ensuring safe and effective fluid transfer.

Advantages of BSPT Connections

The adoption of BSPT connections in various fittings offers several advantages:

- Leak Prevention: The tapered design of BSPT threads provides better sealing, which is crucial for pressure handling and fluid management.

- Versatility: BSPT connections can be found in a wide variety of fittings, making them suitable for different applications.

- Durability: The materials used in BSPT fittings are often robust, ensuring longevity even under tough conditions.

- Ease of Use: BSPT-threaded fittings are relatively easy to install and maintain, making them user-friendly for technicians.

Choosing the Right BSPT Fittings for Your Applications

Selecting the appropriate BSPT fittings is critical for ensuring the efficiency of your system. Consider the following factors:

1. Pressure Requirements

Identify the operational pressure of your system. Ensure that the BSPT fittings you choose have ratings that meet or exceed these requirements to prevent failures.

2. Compatibility with Materials

Different fittings may be made from various materials. Ensure compatibility with the fluids being transported to avoid chemical reactions or degradation over time.

3. Size and Threading

Verify the size and threading specifications of your pipes to select appropriate BSPT fittings that will connect seamlessly.

Installation and Maintenance of BSPT Connections

Proper installation and regular maintenance are vital for the longevity and performance of BSPT connections.

Installation Tips

- Clean Surfaces: Ensure that the connecting surfaces are clean and free of debris.

- Tighten Properly: Avoid over-tightening, as this can damage the threads or fittings. Always follow the manufacturer's specifications.

- Use Sealants Wisely: Although BSPT threads are designed to seal, using appropriate thread sealant can enhance leak prevention.

Maintenance Best Practices

To maintain the integrity of your BSPT connections, consider the following:

- Regular Inspections: Schedule regular inspections of the fittings to identify any signs of wear or leaks.

- Replace Worn Fittings: Promptly replace any fittings that show signs of damage.

- Monitor Pressure Levels: Regularly check the pressure levels to ensure they remain within the recommended limits.

Common Myths About BSPT Connections

As with many technical topics, several myths surround BSPT connections. Here are a few common misconceptions:

1. BSPT and NPT are Interchangeable

While both BSPT (British Standard Pipe Tapered) and NPT (National Pipe Thread) are tapered threads, they have different angles, which means they are not directly interchangeable.

2. All BSPT Fittings Are the Same

BSPT fittings come in various materials, sizes, and configurations, making it essential to choose the right one based on specific system needs.

3. Sealing is Always Guaranteed

While BSPT connections offer reliable sealing, proper installation and maintenance are critical for achieving this. Poorly installed fittings can still leak.

Conclusion

The BSPT connection is a cornerstone of reliable and efficient fluid systems across various industries. From tube fittings to valves, the versatility and durability of BSPT connections make them indispensable in ensuring the safety and efficiency of operations. Understanding their characteristics, applications, and proper maintenance will empower professionals to make informed decisions and maintain the integrity of their systems. Explore more about BSPT connections and fittings on techtubes.in.